Floor Protection Sheets: Manufacturing and Benefits

Floor protection sheets are essential tools used in various industries and construction projects to shield flooring from damage during construction, renovation, or even during everyday use. The demand for these sheets has surged due to their efficiency in maintaining floor integrity and reducing repair costs. This article delves into the manufacturing process of floor protection sheets, the types available, and their numerous benefits.

1. Understanding Floor Protection Sheets

Floor protection sheets are designed to safeguard flooring surfaces from physical damage, dust, paint spills, and other potential hazards. They come in various materials such as plastic, paper, and composite, each tailored for specific applications. Their primary purpose is to preserve the condition of floors and ensure they remain clean and undamaged throughout various processes.

2. Manufacturing Process

a. Material Selection:

The first step in manufacturing floor protection sheets is selecting the appropriate raw materials. The choice depends on the intended use, the type of flooring being protected, and the level of protection required. Common materials include:

- Plastic Films: Polyethylene (PE) and polypropylene (PP) are popular due to their durability and water resistance.

- Paper-Based Sheets: Often used for temporary protection, they are biodegradable and ideal for low-impact applications.

- Composite Materials: These combine plastic and paper to offer enhanced strength and durability.

b. Extrusion and Formation:

For plastic-based sheets, the extrusion process involves melting plastic pellets and forming them into thin sheets. The extruded plastic is then cooled and rolled into large coils. This method ensures a uniform thickness and consistency across the sheets.

c. Coating and Laminating:

To enhance the protective qualities, additional coatings or laminations may be applied. For example, anti-slip coatings are added to prevent accidents, and waterproof laminations ensure that spills do not seep through the sheet. These coatings are applied through various techniques, including spraying or roller coating.

d. Cutting and Packaging:

Once the sheets are formed and treated, they are cut into various sizes based on customer requirements. The sheets are then packaged, typically in rolls or flat packs, for distribution. Quality control checks are performed to ensure that each sheet meets the required standards.

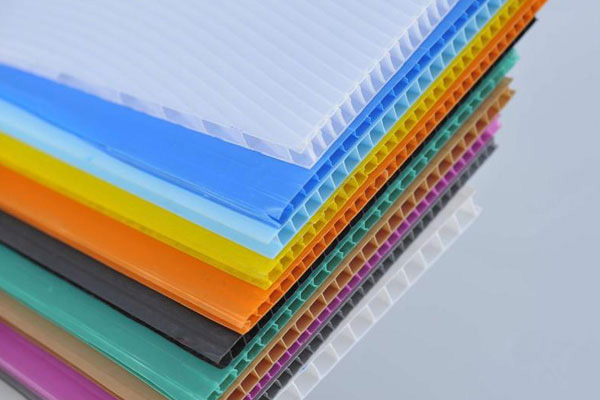

3. Types of Floor Protection Sheets

a. Plastic Sheets:

Plastic floor protection sheets are the most common and are known for their durability and resistance to moisture. They are available in various thicknesses and sizes, making them suitable for different types of flooring and project scales. They are often used in construction sites and during renovations.

b. Paper-Based Sheets:

Paper-based protection sheets are environmentally friendly and are ideal for lighter-duty protection. They are used in less demanding environments where there is minimal risk of heavy impact or chemical exposure. They are also cost-effective and easily disposable.

c. Composite Sheets:

Composite floor protection sheets combine the benefits of both plastic and paper. They offer a balance of durability and environmental friendliness, making them suitable for a wide range of applications. These sheets are often used in commercial settings and high-traffic areas.

4. Benefits of Floor Protection Sheets

a. Damage Prevention:

The primary benefit of floor protection sheets is their ability to prevent damage. They shield floors from scratches, dents, and stains caused by construction materials, heavy equipment, or daily foot traffic. This helps in maintaining the aesthetic appeal and longevity of the flooring.

b. Cost Efficiency:

By preventing damage, floor protection sheets reduce the need for costly repairs and replacements. This is particularly beneficial in large-scale projects where multiple areas are being worked on simultaneously.

c. Easy Application and Removal:

Floor protection sheets are designed for ease of use. They can be quickly applied and removed, minimizing disruption to ongoing activities. This convenience is especially valuable in busy construction sites or during rapid renovations.

d. Versatility:

Different types of floor protection sheets cater to various needs. Whether it’s a high-traffic area requiring durable plastic sheets or a delicate surface needing paper-based protection, there is a suitable option for every scenario.

e. Environmental Impact:

Modern manufacturing processes and materials focus on reducing environmental impact. Many floor protection sheets are recyclable or biodegradable, aligning with eco-friendly practices and contributing to sustainability efforts.

5. Applications

a. Construction Sites:

In construction, floor protection sheets are crucial for protecting new flooring installations from damage caused by construction debris, heavy machinery, and worker traffic.

b. Renovations:

During home or office renovations, floor protection sheets prevent damage from paint spills, dust, and furniture movement, ensuring that the existing flooring remains in good condition.

c. Commercial Use:

Retail and commercial establishments use floor protection sheets to maintain the appearance of their floors during events, sales, or maintenance activities.

d. Residential Use:

Homeowners use floor protection sheets during DIY projects or when moving furniture to protect their flooring from scratches and dents.

6. Conclusion

Floor protection sheets play a vital role in preserving the condition of floors across various settings. The manufacturing process, which includes material selection, extrusion, coating, and packaging, ensures that these sheets meet high standards of quality and effectiveness. With a range of types available, from plastic to paper-based and composite options, there is a floor protection solution for every need. Their benefits—such as damage prevention, cost efficiency, and ease of use—make them an invaluable component in construction, renovation, and daily maintenance. As environmental concerns grow, the industry continues to innovate with more sustainable options, contributing to a greener future while maintaining the integrity of floors worldwide.